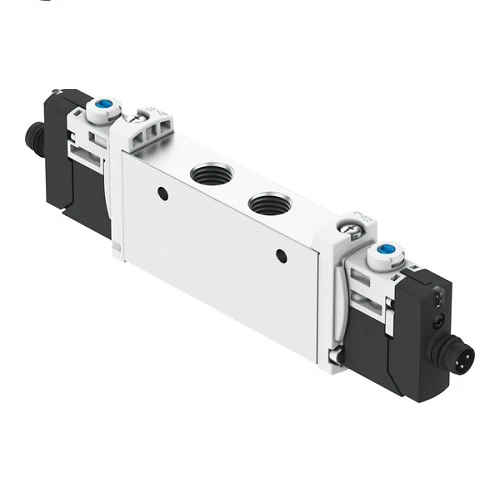

VUVG-L14-T32C-AT-G18-1R8L – Air Solenoid Valve – Festo Directional Control Valves

USD $ 64.02 USD $ 52.50

SKU: Festo 574226

Manufacturer Part Number: Festo 574226

Festo Directional Control Valves: VUVG-L14-T32C-AT-G18-1R8L

OEM Spec Ref

The Festo VUVG-L14-T32C-AT-G18-1R8L directional control valve is a highly efficient and reliable component engineered for precise control in pneumatic systems. With its robust design and advanced technology, this valve is ideal for a wide range of industrial applications.

Key Features:

- Superior Control: Features a 2×3/2-way configuration, monostable, closed function, ensuring accurate control of air flow and direction.

- High Performance: Offers a standard nominal flow rate of 560 l/min, allowing for efficient operations across various conditions.

- Durable Construction: Crafted with high-quality materials, this valve is designed to withstand challenging industrial environments, ensuring longevity and reliability.

- Compact Design: With a valve size of 14 mm and a pneumatic working port of G1/8, it is perfect for installations where space is at a premium.

- Electrical Actuation: Operates on a 24V DC voltage, featuring an electrical actuation type that ensures responsive and stable operations.

Benefits:

- Enhanced Operational Efficiency: Optimizes air flow and pressure, which contributes to the overall efficiency and performance of pneumatic systems.

- Cost-Effective: Reduces maintenance costs and downtime by providing a reliable and long-lasting solution for your control needs.

- Versatile Application: Can be seamlessly integrated into various pneumatic systems, making it a flexible option for many industrial uses.

Applications:

- Automation Systems: Ideal for automated systems requiring precise control of actuation and sequencing.

- Manufacturing: Essential in manufacturing environments for controlling machinery and process flows.

- Testing Equipment: Suitable for use in testing setups where precise air control is necessary to maintain consistent results.

The Festo VUVG-L14-T32C-AT-G18-1R8L stands out as a premium choice for businesses looking to enhance their pneumatic control capabilities, ensuring peak performance and reliability.

Technical Data

| Feature | Specification |

|---|---|

| Valve function | 2×3/2, closed, monostable |

| Actuation type | Electrical |

| Valve size | 14 mm |

| Standard nominal flow rate | 560 l/min |

| Pneumatic working port | G1/8 |

| Operating voltage | 24V DC |

| Operating pressure | 0.15 MPa … 0.8 MPa |

| Operating pressure | 1.5 bar … 8 bar |

| Structural design | Piston gate valve |

| Reset method | Pneumatic spring |

| Certification | RCM compliance mark c UL us – Recognized (OL) |

| Degree of protection | IP65 With plug socket |

| Nominal width | 4.6 mm |

| Exhaust air function | With flow control option |

| Sealing principle | Soft |

| Mounting position | Any |

| Manual override | Detenting Non-detenting Covered |

| Type of control | Pilot-controlled |

| Pilot air supply port | Internal |

| Symbol | 00992904 |

| Lap | Overlap |

| Pilot pressure MPa | 0.15 MPa … 0.8 MPa |

| Pilot pressure | 1.5 bar … 8 bar |

| Suitability for vacuum | no |

| Switching time off | 25 ms |

| On switching time | 9 ms |

| Duty cycle | 100% |

| Max. positive test pulse with 0 signal | 700 µs |

| Max. negative test pulse on 1 signal | 900 µs |

| Coil characteristics | 24 V DC: 1.0 W |

| Permissible voltage fluctuations | +/- 10 % |

| Operating medium | Compressed air as per ISO 8573-1:2010 [7:4:4] |

| Information on operating and pilot media | Operation with oil lubrication possible (required for further use) |

| Vibration resistance | Transport application test with severity level 2 as per FN 942017-4 and EN 60068-2-6 |

| Restricted ambient and media temperature | -5 – 50 °C Without holding power reduction |

| Shock resistance | Shock test with severity level 2 as per FN 942017-5 and EN 60068-2-27 |

| Corrosion resistance class (CRC) | 2 – Moderate corrosion stress |

| LABS (PWIS) conformity | VDMA24364-B1/B2-L |

| Temperature of medium | -5 °C … 60 °C |

| Ambient temperature | -5 °C … 60 °C |

| Product weight | 89 g |

| Electrical connection | Via electrical sub-base |

| Type of mounting | Optionally: On terminal strip With through-hole |

| Pneumatic connection 1 | G1/8 |

| Pneumatic connection 2 | G1/8 |

| Pneumatic connection 3 | G1/8 |

| Pneumatic connection 4 | G1/8 |

| Pneumatic connection 5 | G1/8 |

| Note on materials | RoHS-compliant |

| Seals material | HNBR NBR |

| Housing material | Wrought aluminum alloy |

| Weight | 0.089 kg |

|---|