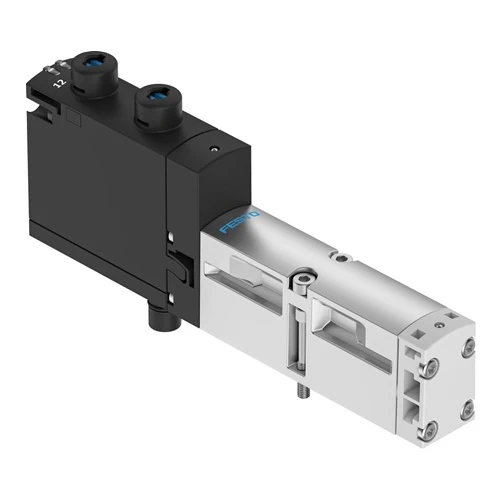

VSVA-B-P53ED-ZD-A2-1T1L – Air Solenoid Valve – Festo Directional Control Valves

USD $ 149.38 USD $ 122.49

SKU: Festo 8031814

Manufacturer Part Number: Festo 8031814

Festo Directional Control Valves: VSVA-B-P53ED-ZD-A2-1T1L

OEM Spec Ref

The Festo VSVA-B-P53ED-ZD-A2-1T1L directional control valve, with MPN 8031814, is a sophisticated solution designed to enhance the control and efficiency of pneumatic systems. This high-quality solenoid valve ensures reliable operation and precision in various industrial applications.

Key Features:

- Advanced Valve Functionality: Utilizes a 5/3 configuration with double solenoids and an exhaust center position, offering flexible control options for pneumatic operations.

- Electrical Actuation: Features electrical actuation for precise control, providing a dependable response to system commands.

- Durable and Reliable: Constructed with a robust die-cast aluminium and polyamide housing, ensuring long-term durability even in demanding industrial environments.

- Compact Design: With a width of 18 mm, this valve is designed to fit seamlessly into compact spaces without compromising on performance.

- High Flow Rate: Offers a standard nominal flow rate of 380 l/min, suitable for efficient handling of air flow in various pneumatic setups.

Benefits:

- Enhanced Operational Efficiency: By providing precise control over air flow, it significantly enhances the efficiency and reliability of pneumatic processes.

- Cost-Effective Operation: Optimizes air consumption, which can lead to reduced energy costs and operational expenditures.

- Extended Equipment Life: Reliable and accurate control helps to minimize wear and tear on other pneumatic components, extending their operational lifespan.

- Versatility: Compatible with a wide range of pneumatic systems, allowing for flexible integration into existing setups.

Applications:

- Automated Manufacturing: Ideal for use in automated production lines where precise pneumatic control is crucial.

- Control Systems: Essential for applications requiring accurate modulation of air flow and pressure.

- Testing and Inspection: Suitable for systems that depend on consistent pressure for accurate testing and diagnostics.

- General Industrial Use: Applicable across various industries due to its versatility and reliability in controlling pneumatic operations.

The Festo VSVA-B-P53ED-ZD-A2-1T1L stands out as a prime example of Festo’s commitment to quality and innovation in pneumatic technology, offering a reliable and efficient solution for managing directional control in industrial processes.

Technical Data

| Feature | Specification |

|---|---|

| Valve function | 5/3, exhausted |

| Actuation type | Electrical |

| Width | 18 mm |

| Standard nominal flow rate | 380 l/min |

| Pneumatic working port | Sub-base, size 18 mm as per ISO 15407-1 G1/8 |

| Operating voltage | 24V DC |

| Operating pressure | -0.09 MPa … 1 MPa |

| -0.9 bar … 10 bar | |

| Structural design | Piston gate valve |

| Reset method | Mechanical spring Electrical actuation |

| Degree of protection | IP65 NEMA 4 |

| Nominal width | 5 mm |

| Exhaust air function | With flow control option Via throttle plate Via individual sub-base |

| Sealing principle | Soft |

| Mounting position | Any |

| Manual override | Detenting Non-detenting |

| Type of control | Pilot-controlled |

| Pilot air supply port | External |

| Flow direction | Non-reversible |

| Symbol | 00992824 |

| Lap | Overlap |

| Signal status display | LED |

| Pilot pressure MPa | 0.3 MPa … 1 MPa |

| Pilot pressure | 3 bar … 10 bar |

| Flow rate of pneumatic valve on individual sub-base | 390 l/min |

| Optimized flow rate of pneumatic valve, pneumatically concatenated flow | 430 l/min |

| Optimized flow rate of pneumatic valve pneumatically concatenated flow | 380 l/min |

| Asymmetrical switching time off | 37 ms for control side 12 |

| Asymmetrical switching time on | 10 ms for control side 14 13 ms for control side 12 |

| Duty cycle | 100% |

| Max. positive test pulse with 0 signal | 1500 µs |

| Max. negative test pulse on 1 signal | 800 µs |

| Nominal operating voltage DC | 24 V |

| Coil characteristics | 24 V DC: 1.6 W |

| Surge resistance | 2.5 kV |

| Contamination level | 3 |

| Permissible voltage fluctuations | +/- 10 % |

| Operating medium | Compressed air as per ISO 8573-1:2010 [7:4:4] |

| Information on operating and pilot media | Operation with oil lubrication possible (required for further use) |

| Vibration resistance | Transport application test with severity level 2 as per FN 942017-4 and EN 60068-2-6 |

| Shock resistance | Shock test with severity level 2 as per FN 942017-5 and EN 60068-2-27 |

| Corrosion resistance class (CRC) | 0 – No corrosion stress |

| LABS (PWIS) conformity | VDMA24364-B1/B2-L |

| Temperature of medium | -5 °C … 50 °C |

| Relative air humidity | 0 – 90 % |

| Noise level | 85 dB(A) |

| Ambient temperature | -5 °C … 50 °C |

| Max. tightening torque for valve mounting | 0.8 Nm … 1.2 Nm |

| Product weight | 170 g |

| Electrical connection | 4-pin Plug as per ISO 15407-2 |

| Type of mounting | On sub-base |

| Pilot air port 12/14 | Sub-base, size 18 mm as per ISO 15407-2 |

| Pilot exhaust air port 82/84 | Ducted Not ducted Optionally: |

| Pneumatic connection 1 | Sub-base, size 18 mm as per ISO 15407-2 |

| Pneumatic connection 2 | Sub-base, size 18 mm as per ISO 15407-2 |

| Pneumatic connection 3 | Sub-base, size 18 mm as per ISO 15407-2 |

| Pneumatic connection 4 | Sub-base, size 18 mm as per ISO 15407-2 |

| Pneumatic connection 5 | Sub-base, size 18 mm as per ISO 15407-2 |

| Note on materials | RoHS-compliant |

| Seals material | FPM NBR |

| Housing material | Die-cast aluminum PA |

| Material of screws | Steel, galvanized |

| Weight | 0.170 kg |

|---|